Introduction to Vertical Machining

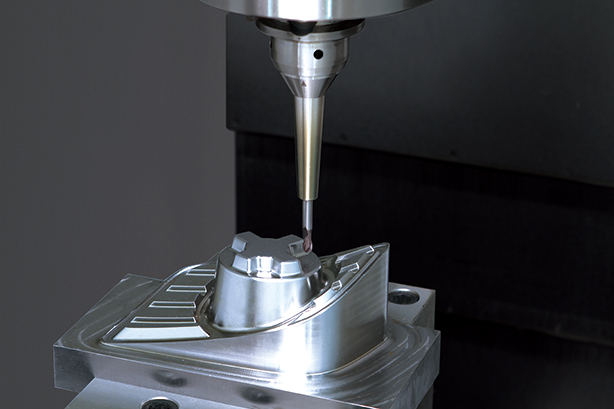

VMC Milling Machine has been in its most basic sort for more than 150 years. However, it’s as yet during all|one amongst|one in each of} the latest styles of machining innovation (turning/machines is that the most seasoned). The technique for “Milling” involves a turning shaper or penetrating piece, and a portable work table, to which the work is join.

The shaper is connecte to and turned into a lodging called the “shaft.” Through the sharpness of the device and power of the table driving the texture into the shaper, the material yields and is remove or whiskerless as want. The pivot of power might be up/down (alluded to because of the Z-Hub), left/right (allude to as the X-Hub), or front to back (alluded to as the Y-Hub).

The Original Milling Machine

VMC Milling Machine might be furnished with different changes. For instance, there are a few points of approach out there similar to revolving and elective situating gadgets side by the side of the worktable. Later versions of the VMC Milling Machine style had extra power and pressure-driven taking care of gadgets to make the framework more programmed. In the long run, handled controls were add to allow for more robotization in activity, repeatability, device choice/changing and shape control. These new CNCs took the “milling” machine to a substitution level of efficiency, and consequently, the term VMC (Vertical Machining Center) was conceived.

The CNC And VMC Machine: Rudiments of the strategy

VMC Milling Machine are utilized principally (albeit not exclusively) as metal-removing machines that take steel, Al, or option burdensome materials — consequently, moulding a crude block of texture into an accurately framed or “machined” surface.

VMC Milling Machine might be used for not exclusively cutting but conjointly penetrating, cutting, etching, tapping, subsetting, chamfering, and heaps of different applications. Due to their capability and similarly minimal expense. They’re exceptionally normal machines that are tracke down in outlets worldwide. The probability is reasonable that there’s a machine functional just several miles from where you’re perusing this at this point.

VMCs all utilization a shared trait of parts, that are as per the following:

Pivoting Shaft — The Shaft, opposite the working surface or table, will hold a scope of cutting instruments (or factories as they are for the most part called). The shaft cartridge is mounte in an extreme lodging impact all over — this movement heading is known as the Z-Pivot.

Table — The Table might be a stage to mount workpieces — either straightforwardly or through a scope of installations like cleaned Al plates or cumbersome bracing tight clamps. The table incorporates a movement of left and right, which we watch out for, the X-Pivot, and front to back, named the Y-Hub. These 2 tomahawks of movement, notwithstanding the Z-Pivot, manage the cost of limitless shaping across the planes of movement.

Additional Normal parts

Device Transformer — An instrument transformer significantly will expand a CNC Machining Components efficiency by allowing for the programmed, PC-controlled selection of instruments for a scope of undertakings from unpleasant slicing to fine opening exhausting.

Cooling — To keep components and cutters cool and greased up, most VMC Milling Machine utilize some recycling liquid framework; regularly, a mix of dissolvable oil and water might be various elective fluids too.

Chip/Screw Transport — To clear the chips from the work zone, different chip transports and chip drills are additionally used to expand efficiency and scale back the period from physically scooping out squandered chips.

Full Covers/Walled in areas — These can be extra proportional back the sprinkle/splatter brought about by milling activities and shield the administrators and environment from the machining system.

Pivoting Tables — Adding extra Tomahawks to the machine will incredibly expand its efficiency by transforming a direct three-hub machine into a four-or perhaps five-hub framework fit for machining muddled leaves behind shifted surfaces (like revolving motor sharp edges).

Quick Stacking Loaders — One more invite expansion to extensively expand efficiency is the utilization of transport tables or other programmed half-stacking frameworks. These can diminish the period and increment most CNC Vertical Milling Machine frameworks’ axle “ON” season.

Normal Purposes of VMC Milling Machine Include: Machining components for delivering congregations, castings, auto, shape/pass-on making, and bunches of elective metal cutting errands.

Normal Businesses abuse These Cycles:

- Auto Industry,

- Shipbuilding,

- Machine Shops,

- Machinery Developers, and

- Creating Industry.

At Southern Creating Machinery Deals, we have enormous milling Frameworks and Vertical Machining Focuses. Notwithstanding our staff’s data of those strong frameworks, we will be your best inventory for Milling, Turning, EDM, Creation, and Plastics machinery. Choice us these days at 9978922288 or visit us online at www.keytexmachines.com